By Don Jones.

After the mining boom ended in Kalgoorlie in 1937 my parents moved to Yarloop. My father got a job as a boiler maker’s assistant with Millars’ Timber Workshop, which did all of the maintenance for the timber mills in the South West.

My primary schooling was at Yarloop, then I and others in the district were bussed each day to Harvey Junior High School to continue our education. In May 1950 in my third year, at the principal’s suggestion, I successfully applied for an apprenticeship as a Pattern Maker at Millars’. The principal also arranged for me to go by train to Harvey for half a day each week to collect lessons prepared by my teachers to work on at home. I passed all eight subjects in the Junior Examination.

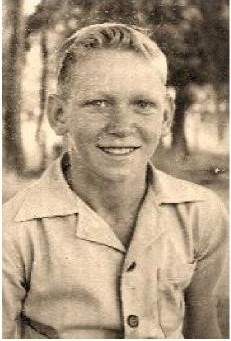

Don aged 14

Pattern Makers make models in wood or metal, around which sand is packed. When the pattern is removed the resulting cavity in the sand is the exact shape of the object to be cast. This is then filled with molten metal to form a casting. While the moulder is responsible for the general design, it is the Pattern Maker who is responsible for constructing the form used for moulds.

When I was 16 my parents had to move to Perth because of my Mother’s poor health. I remained in Yarloop living in the single men’s quarters, surviving on my very basic apprentice wage.

Don’s toolbox made by him in 1955. He decided to donate it to the Yarloop museum but fortunately had not gotten around to it before the disastrous Yarloop Fires!

Nearing the end of my apprenticeship National Service came in, but I was given a three-month amnesty which allowed me to come to Perth to be with my parents. I found work at Hoskins Foundry for two years where, while working as a tradesman, I completed my apprenticeship then at McAllister’s who were contract pattern makers. My main work there was in creating valves and gears for steam equipment and engines. I also patterned ships’ propellers, rudders and drive shafts.

Over the years I have made a lot of furniture for my family. When I was courting Claire, as a surprise, I made her a glory box in the form of a china buffet cabinet, put it on my father’s trailer and took it from my Subiaco home to Claire’s in Mt Hawthorn. One of Claire’s friends saw it in transit and commented that it looked exactly the same as hers. However, hers was bought, Claire’s was made with love.

With the advent of materials like plastics and the decline in demand for pattern making, I studied for a Diploma in Management Studies at TAFE. I then took a job as a salesman selling valves, before Claire and I spent three years in Melbourne running a valve industry business. Returning to Perth we bought an established business, Northern Machinery in Balcatta, specialising in power tools and woodworking machinery.

It is unfortunate, that like many crafts, pattern making is not as prominent as it was. My life has been busy though and I have been fortunate to have had the support of Claire and my family.[1]

……………………………………………………………

[1] From ‘The Phoenix Rises Very Slowly’ Part 12. This article, ‘The Art of Pattern Making, Don Jones’ as related to Linley Wakefield.